Integration Services Overview...

Closely related to our core business of supplying high performance optical systems and tracking mounts is our capabilities for Integration Services.

Custom Optics and Telescopes

Over the years RCOS has been involved in designing and building many custom, state-of-the-art Optical Systems. Optics (telescopes) performance is always a critical factor in an Optical Tracking System. We can optimize the optical prescription for encircled energy performance, desired FOV, spectral requirements, and customer-provided f-number and focal length specifications. We provide interferograms for all of our mirrors. We can meet desired transmissive performance on optical windows and choose coatings to meet reflectivity specifications. One of our specialties is designing Telescopes for use in IR bands. We do complete camera and mounting integrations. This might involve the use of beam splitters, fast steering mirrors, special materials, or even custom electronics. We pay particular attention to using low coefficient of expansion materials, and the stability requirements for the mirror support systems used with optics subjected to G-forces (covering elevations from horizon to zenith).

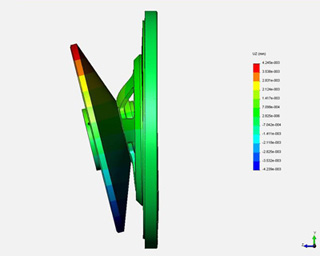

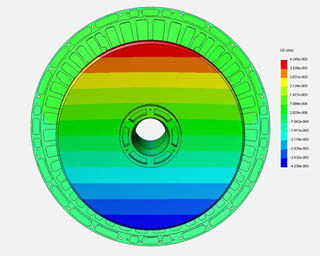

Our in-house engineering department is utilizes CAD, Solid Modeling, and Finite Element Analysis (FEA) for our design work. Before a critical part is machined, FEA is done on the solid model to test for flexure, stress and frequency analysis. For example, we want to measure the deflection of the optics and mirror cell when pointed at or below the horizon. Using SolidWorks, ZEMAX and Cosmos, we can fine tune the design so that the optical performance will meet the customer's expectations.

This shows the displacement due to the mirror weight (side view on left). The deviation scale is ~ 18,500:1. The actual mirror angle is ~ 13.5 micro radians

Carbon Composite Construction

RCOS was first in the industry to make use of carbon fiber composite fabrication techniques as standard construction over a decade ago. Carbon fiber is the ultimate material for telescope manufacturing as it has a near zero co-efficient of expansion (lower than Invar) and a very low specific heat capacity. Many telescope manufactures still use invar, (or quartz), metering rods to stabilize spacing between the primary and secondary mirrors. But these materials are fragile, heavy, and have a high specific heat capacity radiating heat into the light path. Invar is not an ideal material for use in a telescope, while carbon fiber is. RCOS has since demonstrated the advantages of carbon fiber and carbon / Nomex on literally 100s of telescopes.

This ½ wall Carbon / Nomex tube is 29" dia x 72" long and weighs 48 pounds.

RCOS's expertise in composite materials also translates to instrumentation enclosures, lightweight weatherized tracking mounts, and space based telescopes.

Elevation over Azimuth and Equatorial Fork Mounts

RCOS manufactures highly accurate Elevation over Azimuth (EL/AZ) and Equatorial Fork Mounts (EFM). These mounts are performing superbly for astronomical imaging and satellite tracking. Our 32RC (.81m) telescopes installed on the RCOS Equatorial Fork Mounts are taking up to 15-minute unguided exposures. All of these astronomical telescopes/mounts are reporting exceptional sidereal tracking and stability.

We use parametric design principles allowing us to vary the fork width, swing through, and performance characteristics to meet specialized gimbal requirements. We use a family of direct drive motors that can be sized to fit the slew speed requirements. In fact we use multiple types of drive systems i.e. friction drive, worm gear, etc. depending on the intended use.

We design and manufacture our own controller for use with our tracking mounts. We can provide an interface to talk directly to our controller from the customer's application.

Specialized Applications

RCOS also developed an Elevation over Azimuth tracking mount for Space Debris and LEO tracking. It can acquire and track Low Earth Orbit Satellites; and with a maximum slew speed of 20 degrees per second it makes for fast acquisition of the satellite. EL / AZ mounts have inherent field rotation so we developed a Field De-Rotator, a follow-on to our very successful Instrument Rotator. A Field De-Rotator is necessary for long exposure celestial imaging to correct for field rotation. Central to success of LEO acquisition and open loop tracking is accurate modeling of Gimbal and telescope misalignments and flexures. Using Pro-TPoint with an automated mapping routine we have modeled our primary telescope to achieve pointing and tracking accuracies within a population standard deviation of 1.3 arc-seconds (which is 1.1 arc-sec RMS). Once modeled, a mobile system can easily and quickly be calibrated to the sky using a simple 6-10 star map to solve for axis tilt and collimation coefficients.

RCOS also partners with other software developers and hardware suppliers to insure integration of our products for specialized applications or use with other complimentary technologies.